Warehouse

with Jorge Marinho

This straw bale pavilion offers a quiet refuge from the intensity of the Copenhagen Architecture Biennale. The scent of cereal, the soft texture of straw, and the sound dampened interior create a calm, immersive space where visitors can slow down and reflect. Sheltered by a lightweight roof, the stacked bales recall childhood memories of barns and harvests—inviting a return to simplicity. Inside, visitors can rest, breathe, and rediscover the Biennale at a gentler pace. A moment of the Danish countryside in Copenhagen.

Weaving sensory dimensions with sustainability considerations, this pavilion approaches slowing down not only by design but also conceptually.

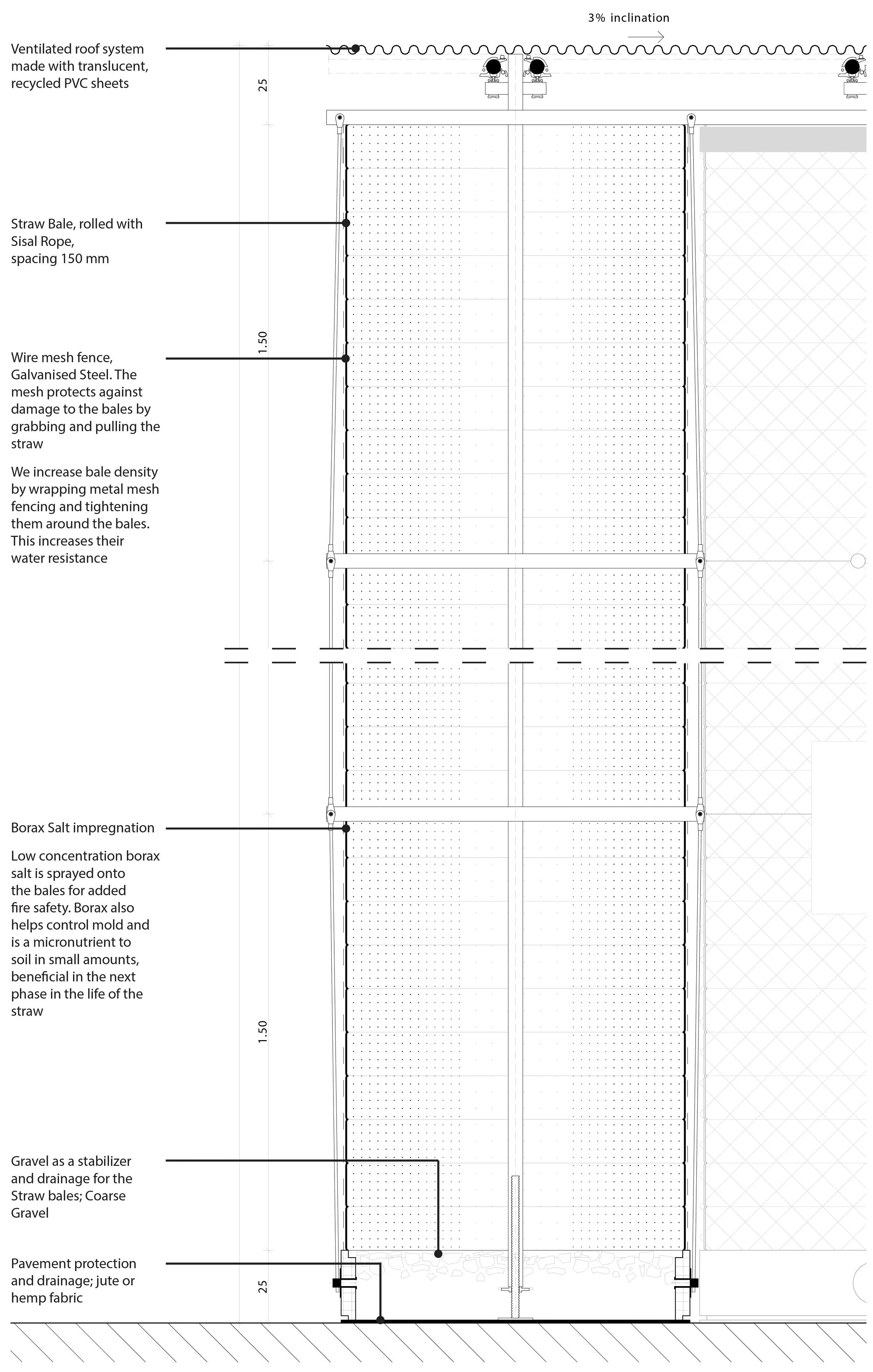

In response to the temporary nature of the Biennale, straw was chosen as the pavilion’s primary material for its multifaceted qualities. Beyond its low environmental impact, straw offers excellent sound insulation, which plays a crucial role in shaping the pavilion’s quiet, introspective atmosphere.

Straw is an agricultural byproduct of cereal. When the grain is removed, the stalk is left as straw. After separation, the straw is left to dry in the field. Once it reaches ~15% humidity, the straw is crushed and baled. After this process, the bales end up stored in the field or under shelter.

Placed in the eastern end of the Gammel Strand square stands a pavilion where you take a second to breathe in the busy old town of the capital. Rotated 45 degrees, it gently shields visitors from view, creating a sense of calm and rural character.

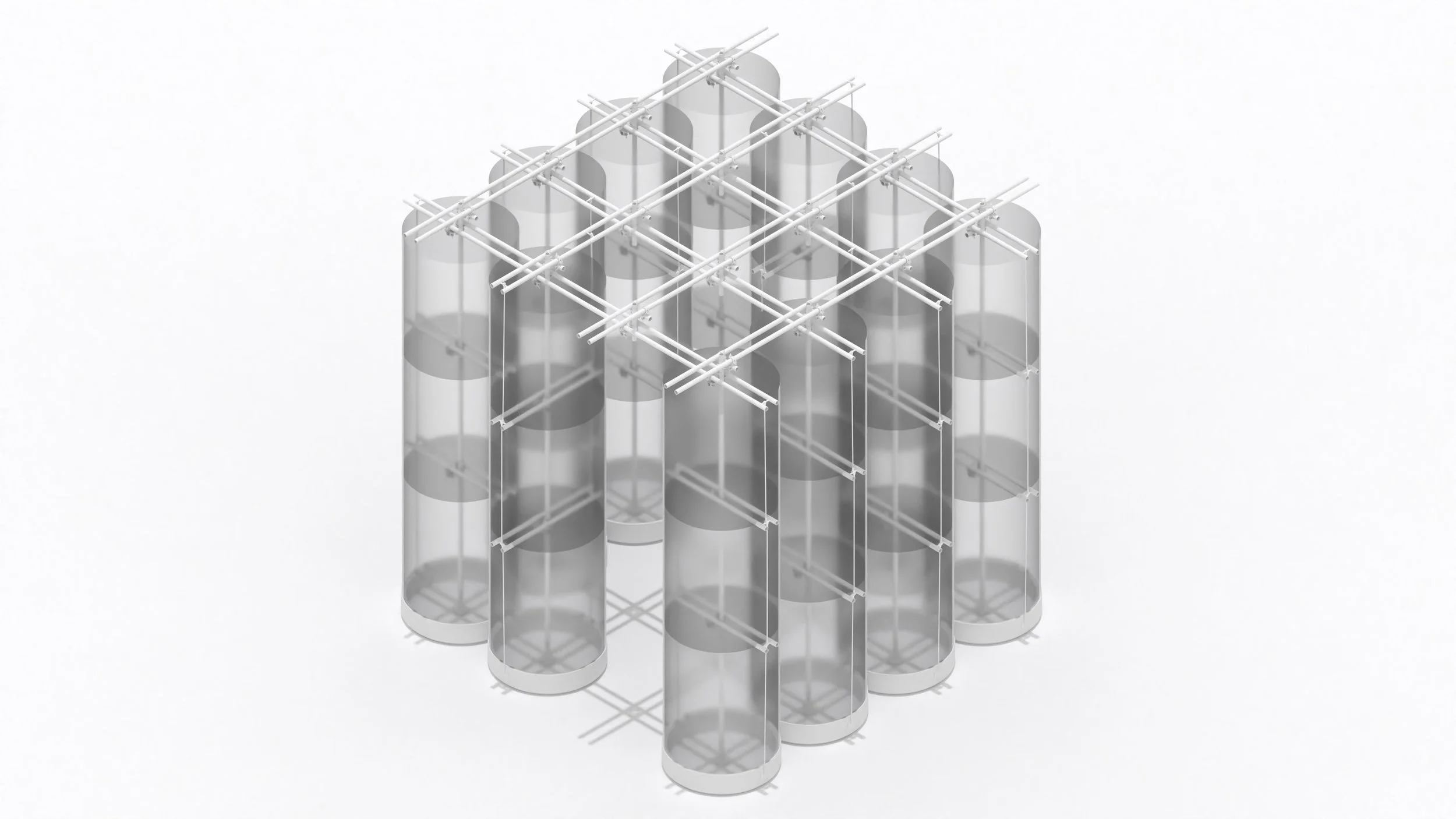

The role of the bales as a pavilion is just one moment in their evolving life cycle being repurposed after the fair ends. The stacked form reflects a traditional storage method seen throughout history—practical, familiar, and ever adaptable. The smallest unit of the pavilion is a bale; the design of the pavilion comes from simply repeating this unit. Bales come in standard sizes of 1200 mm diameter and 1500 mm high. These standard elements give the dimension of the pavilion.

The primary material of the pavilion begins its lifecycle as cereal crops grown in fields. Once harvested and separated from their nutritious grains, the remaining straw is repurposed for construction. After the biennale, this material is upcycled: the weathered portions serve as a substrate for mushroom cultivation, while the intact straw is reused in compressed construction systems.

Additionally, the straw could later be repurposed as livestock feed, continuing its utility in agricultural cycles. A dense bale is more resistant to moisture penetration. Wrapping it tightly makes it more dense. We propose wrapping the bale with a metal mesh to protect it from damage.

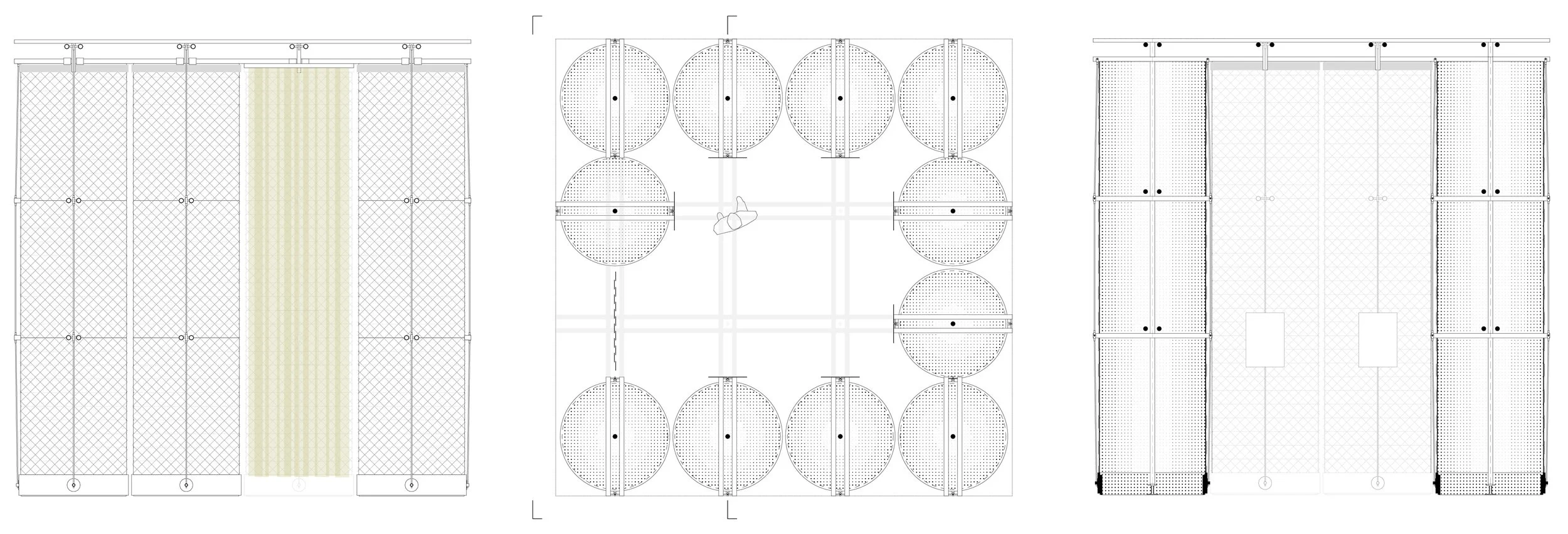

To address the static constraints, we selected a material capable of keeping the bales securely bound together. Due to their diameter and compression strength, the bales can support their own weight, a characteristic commonly observed on farms where bales are stacked atop one another. In this design, a scaffold system serves as a stabilizing strategy, reinforcing the pavilion structure and compressing the bales together. The scaffold extends across the cantilevered sections between the bales, supporting a lightweight transparent roof.

The use of standard tubular elements and joints within the scaffold system enhances its modularity, allowing for quick assembly and disassembly. This modular approach not only ensures structural stability but also enables efficient dismantling and reuse at the end of the fair.

The design of the project thoughtfully considers each stage of construction, aiming to ensure an efficient assembly and disassembly process.

The process begins by protecting the floor with a flexible membrane. A manhole ring is then positioned, aligned with the base of the scaffold structure at its center. The interior is subsequently filled with gravel, providing a stable foundation.

Straw bales are placed horizontaly to form columns, over a metal mesh. Each set of three bales is pierced through the center with a scaffold tube for internal support. Once a column is wrapped in metal mesh and secured with tension cables, it is lifted and inserted into the manhole ring at the scaffold’s base.

After all columns are installed, the scaffold elements forming the roof are assembled. These upper components interconnect and lock the system together as a cohesive whole.

The structural framework of the pavilion is envisioned as a rented system, sourced specifically for the duration of the fair. Once the event concludes, the scaffolding is disassembled and returned, minimizing material waste and reinforcing the project’s commitment to reusability and resource efficiency.